Why do over a billion people still lack basic human necessities, when hundreds of billions of dollars in foreign aid and private charity have been distributed in the last 25 years?

The problem with traditional charity is not only that it must overcome the known problems—administrative overhead, corruption, waste—but that it is premised on a zero-sum redistribution, with little or no thought to the power of incentives or the necessity of self sufficiency. From my experiences, I have seen that even the most destitute person, once he receives enough food for the next week, often takes no further action for the remainder of the week. Needless to say, many recipients have become trained to anticipate handouts.

With this problem in mind, I have sought out solutions with the most asymmetrical, multi-pronged impact. I have created an innovation prize, the K Prize, that is based on the power of incentives and addresses the persistence of global poverty. It is a prize for innovators in the burgeoning field of 3D printing for personal manufacturing.

Why 3D printing for personal manufacturing? An industrial infrastructure that can provide the products and employment needed to elevate average people in emerging economies to an intermediate level of human development can take decades to build. With the success of China in assimilating so much of the global economy’s low-cost manufacturing output, many of the world’s poorest nations have no opportunity to construct and secure their own manufacturing sector. Hence, this stage of industrial development has become a chasm that many nations are finding difficult to cross.

Are you enjoying this article? Read more like this, plus SSIR's full archive of content, when you subscribe.

But if manufacturing itself can be brought to the scale that cottage industries operate in, then the scale of Chinese mass manufacturing is no longer a requirement to be cost competitive. A technology that removes the fixed costs and volume necessities associated with manufacturing can reduce the barriers to entry for the manufacturing of many commodity goods, creating a “long tail” effect.

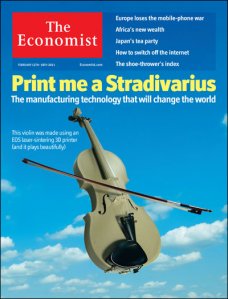

The technology to print solid objects (much like an inkjet printer, except that thousands of layers are successively printed until the object is complete) is becoming reliable and affordable. The Economist featured the technology in its Feb. 10, 2011 cover story, stating: “The industrial revolution of the late 18th century made possible the mass production of goods, thereby creating economies of scale which changed the economy—and society—in ways that nobody could have imagined at the time. Now a new manufacturing technology has emerged which does the opposite. Three-dimensional printing makes it as inexpensive to create single items as it is to produce thousands and thus undermines economies of scale. It may have as profound an impact on the world as the coming of the factory did.”

Even more ambitious, a community of inventors has been working on producing a 3D printer that prints copies of its own parts—i.e., a self-replicating printer. This initiative is known as the RepRap project, and has an open-source policy. Many of these inventors pursue the project as a hobby, and thus hesitate to spend a few hundred dollars that might advance the project. A prize could cause team formation and resource pooling, accelerating the technology. Furthermore, the material used in the 3D printing process under RepRap need not be expensive; it can consist of some of the plastics causing environmental problems. Twenty seven million tons of plastic waste produced each year can be redeployed toward the productive use of personal manufacturing.

Like the editors of The Economist and increasingly many others, I believe that this technology could cause a massive paradigm shift in how low-cost manufacturing is done. A machine that could print just about any basic solid object of daily utility, and even print electrical circuits, is useful enough. If the same machine also could print 90 percent of the parts needed to build a copy of itself, then mass distribution of this “personal manufacturing” machine would be extremely efficient.

The K Prize for Personal Manufacturing will be awarded to the innovator who can produce a self-replicating 3D printer. The prize seeks to encourage collaboration and sharing among participants in the RepRap project. The prize of up to $100,000 will consist of an interim prize of $20,000 awarded at the end of 2012, and a grand prize of $80,000 awarded at the end of 2015. Please visit kprize.wordpress.com for details. I intend to demonstrate that with the right vision and incentives, a great deal can be accomplished to reduce poverty and spark an innovation economy in the developing world.

Support SSIR’s coverage of cross-sector solutions to global challenges.

Help us further the reach of innovative ideas. Donate today.

Read more stories by Kartik Gada.